| Category : | PLC |

| Project : | NUCOR |

| Description : | Downcoiler Modernization |

| Year : | 2017 |

| Customer : | Nucor - USA |

| Platform : | LogiCad |

PLC NUCOR Modernization

Project Target

The target was to speed up the rolling process with existing mechanics of the rolling mill and to improve quality of rolled out material.

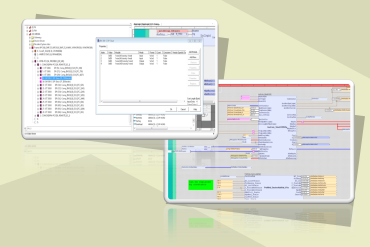

First step was to analyse original SIMADYN D software to find the best solution to keep the compatibilty with existing functions and systems and add new functions.

Second step was to redesign original functions and prepare the software for Logicad platform.

Project made for SMS Group GmbH

Technical data

- Original platform: SIMADYN D

- New Platform : LogiCad

- Fieldbus : ProfiBus, EtherCat

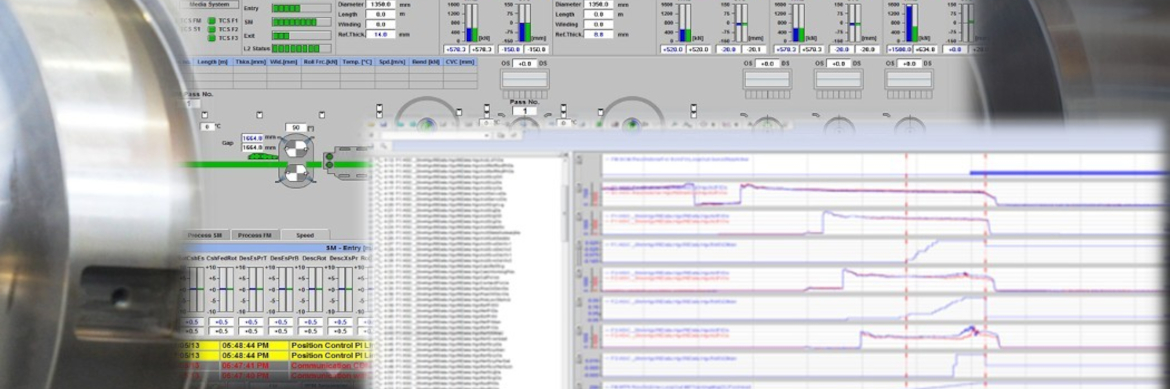

- Diagnostic : IbaAnalyzer

Transport control of rolled out coils:

This system contains the sequential control of automatic transport rolled out coils, including their banding, marking and weighing, up to the rolled out coils store.

Laminar cooling:

The system controling all valves for the delivery of the right amount of cooling water for requested target temperature of each specific material during coiling.

Coil tracking :

The system is tracking all coils from the begining to the end of rolling process. This system is memorizing and monitoring positions and technological informations (coil number, weight, diameter, material code....) of each individual coil in the rolling mill.

Control of all down coiler's drives:

this part contains the control of all synchronous and asynchronous drives and their communications to invertors.

Integration Test phase 1:

This part of integration test was done in Germany at SMS Group GmbH company. Our parts of project software were merged together with the rest of the project software and tested all together. The main point of the integration test is to simulate whole technological entity and test all programmed parts together to reduce the commissioning time at customer.

Integration Test phase 2:

The second phase of integration test was done in testing area of SMS Site Services Inc. company in Pittsburgh PA USA with ultimate customer's representatives presence. The main target of this part of the integration test was to introduce new functions to the ultimate customer.

Commissioning:

The commissioning was done at ultimate custommer in the USA. The main supplier of whole technology and master of whole commisioning was the SMS Site Service Inc. The commissioning included hw signal check, movements check and optimalization of control loops, manual and automatic function check, production start and support.