| Category : | HMI |

| Project : | BRS TF |

| Description : | HMI developement |

| Year : | 2016 - 2017 |

| Customer : | Big River Steel Inc. - USA |

| Platform : | WinCC |

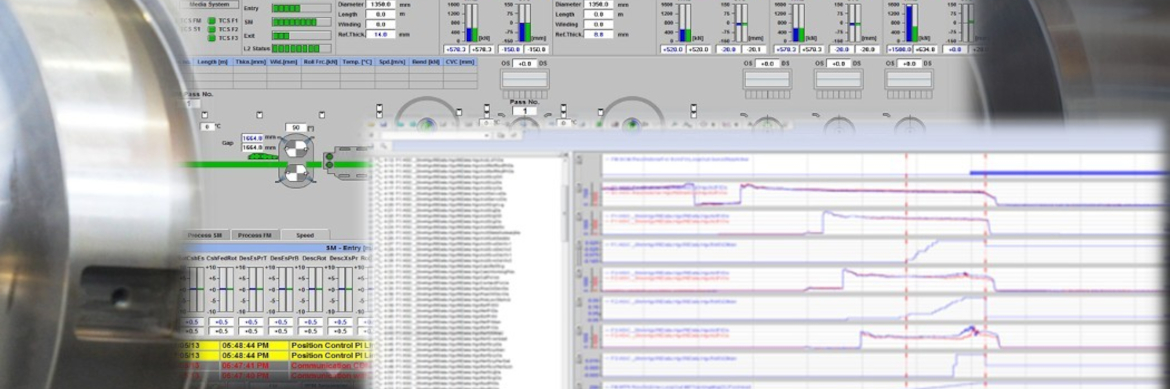

BRS Tunnel Furnace HMI

Project Target

The main target of this project was to design and program parts of HMI (Human Machine Interface) according to the customer's order. The project included also the commissioning at ultimate customer, optimalization and additional modifications. Last but no least part was to provide the technical support by means of Service portal (remote desktop connection).

Project made for SMS Site Services Inc. USA

Technical data

- Platform : WinCC (Win, Win Server)

- Technology : Tunnel Furnace

- Hardware : Server, 2 clients

- Communications : TCP/IP, ODBC, RFM, SQL

- Number of external tags: 42410

- Number of internal tags: 66713

- Number of tags : 109123

Overview screens:

Screens that are collecting all important information for operators or maintainance staff at one place.

Hydraulic screens:

Screens of hydraulic system supporting oil for hydraulical movements.

Furnace control screens:

Screens showing status of all controllers and mechanisms in each part of the furnace.

Material tracking screens during heating up process:

The screens showing positions of head and tail and technological information of each plate in the tunnel furnace.

Diagnostic screens:

Screens for diagnosis to see the status of each part of system.

Error screens:

Screens with errors and warnings overview and posibility to filter them for better investigation of problem.

Master systems data exchange screens:

Screens handling data exchange from and to superior systems.

Technical support:

The technical support by means of the remote desktop and service portal during the sharp production. The remote control technical support allows fast reaction in case of production troubles and rapidly decress eventual financial losses.