| Category : | PLC |

| Project : | BRS TCM/CSP |

| Description : | TCM/CSP automation |

| Year : | 2016 - 2017 |

| Customer : | Big River Steel - USA |

| Platform : | LogiCad |

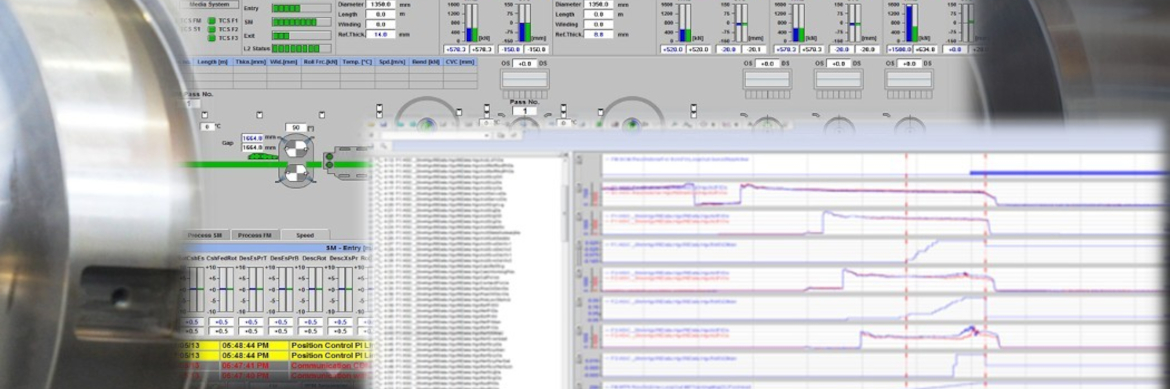

PLC BRS Commissioning

Project Target

The main target of this project was to commission and modify prepared software. The commissioning was splited in two indenpended parts.

1) Compact Strip Production Mill (CSP):

It is the compact hot strip mill which includes casting, heating, rolling and coiling. We participated on entry area of hot rolling mill area.

2) Tandem Cold Mill (TCM):

This Tandem cold mill consists of five mill stands arranged in series to reduce the thickness of the strip gradually in one single pass. We participated on several parts of tandem cold mill process automation.

Project made for SMS Site Services Inc. USA

Technical data

- Platform : LogiCad

- Technology : CSP and TCM

- Fieldbus : ProfiBus, EtherCat

- Diagnostic : IbaAnalyzer

Pendulum Shear control:

This system contains the control of automatic cutting of incoming slab head or tail. It is also giving the chance to chop whole slab to small pieces in the case if it is not possible to roll it.

Entry side guides control:

The system controling all hydraulic valves for positioning of side guides leading the head, body and tail of slab to the right centre line for rolling.

Descaling system :

The system which is providing and controling removing of scale from incoming slab to the rolling proccess. The right amount and pressure of water together with the right distance and angle of spraying nozzles is providing the clean surface of slab before rolling proccess starts.

Control of roller tables:

this part contains the control of all necessary drives to move the slab forward.

Roll change control:

The system for fast change of work rolls in automatic mode (sequentional steps logic) and for backup rolls change.

Coil tracking system:

The system for coils tracking from the beginning of process (entry side of rolling mill) till the end of process (exit side of rolling mill). System is memorizing positions of individual coils in the mill and basic technological information about them (Coil Id, weight, diameter, material code...).

Material tracking system:

The system for tracking material head and end in finnishing or cold mill area. For controling of rolling process is necessary to know exact positions of strip head and end to be able to set the right devices to right positions at the right time so this system calculates them, synchronize them and cooperate with Rolling sequencer to support the best controling of rolling process.

Coil transport:

It is the system of sequentional control of automatic coil transportation from down coiler through the banding machine, weighing device, marking machine up to storage crane take over position.

Master systems communication:

The resource communicating with higher level systems, distributing data and controling the subordinary systems.